4. Particle Size and Micronization

In the world of Permanent Makeup (PMU), the terms "particle size" and "micronization" play crucial roles, although they're often not given the attention they deserve.

Particle Size

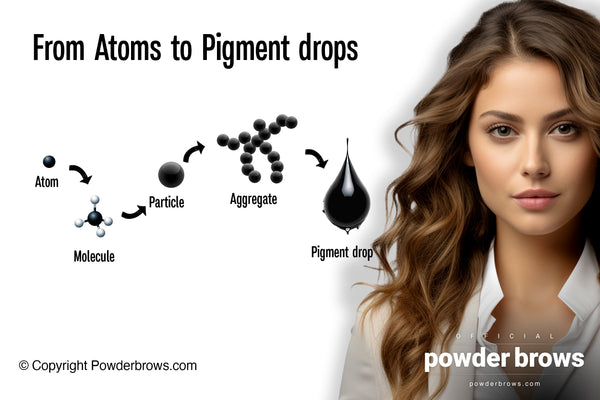

Particle size refers to the dimensions of the individual pigment particles in a PMU formula. This size is usually measured in micrometers (or microns) and can vary widely among different types of pigments. The particle size has a direct impact on various attributes of the pigment, such as its color intensity, how well it disperses in the skin, and its retention.

Larger particles generally offer more vibrant colors but may not disperse as well in the skin. They may also be more prone to fading over time. On the other hand, smaller particles often provide a softer color, disperse more evenly, and are generally more stable, leading to longer-lasting results.

Micronization

Micronization is a crucial process in producing semi-permanent pigments, and it involves grinding pigment particles into finer sizes. This process uses specialized machinery like ball mills or jet mills. The primary goal is to achieve a smoother application and enhanced color payoff when the pigment is used on the skin.

Basically, micronization is the technique of reducing the average diameter of a solid material's particles. While the term usually refers to reducing average particle diameters to the micrometer range, it can also extend to further reduction to the nanometer scale.

Traditional vs. Modern Techniques

Traditional methods for micronization rely on mechanical means such as milling, grinding, and bashing. In a typical industrial mill, a cylindrical metallic drum contains steel spheres that crush the particles to smaller diameters as the drum rotates. These mechanical methods are based on friction and impact to reduce particle size.

On the other hand, modern techniques exploit the properties of supercritical fluids to manipulate solubility principles. These methods include the RESS process (Rapid Expansion of Supercritical Solutions), the SAS method (Supercritical Anti-Solvent), and the PGSS method (Particles from Gas Saturated Solutions). These techniques offer finer control over particle diameters, distribution, and consistency.

Relevance to Semi-Permanent Pigments

In the context of semi-permanent pigments, micronization is pivotal in influencing the pigment's behavior under the skin. The smaller and more consistent the particle size, the smoother the application. This results in a more uniform color distribution and reduces the risk of blotchiness or uneven fading over time.

Furthermore, micronized pigments can offer better stability and longevity. This is because smaller particles have higher dissolution rates, which can, in turn, increase the efficacy and staying power of the pigment under the skin.

Micronization and pigment business

Understanding Micronization from a Producer's Perspective in the Semi-Permanent Makeup Pigment Industry To grasp the significance of micronization, it's crucial to look at it from a producer's standpoint. Typically, producers aim to create pigments that meet several key criteria: legality, cost-effectiveness, and ease of application.

Legal Constraints. If the pigments don't meet legal requirements, then there's no scope for a viable business. Therefore, producers put considerable effort into ensuring that their products adhere to safety standards. At least on paper, everything has to be ok.

Cost-Effectiveness. The second factor is cost. To ensure profitability, producers are always looking for methods to produce high-enough quality pigments at a reasonable cost. Micronization plays an important part in achieving that.

Ease of Implantation. The third factor is the ease with which the pigment can be applied or implanted into the skin. Most artists are not professionals, and thus, the producer needs to create a pigment that is easy enough to implant with a reasonable number of passes and, at the same time, not "sinking in" too easily to prevent migration and blurry edges.

Role of Particle Size. This is where the concept of micronization comes into play. The particles have to be small enough so that they are more opaque in the skin. Spaces between larger particles make those less opaque, and thus, the artists have to implant more of them with a larger number of passes.

Consistency and Composition. Another consideration is the pigment's consistency. Smaller particle pigments often require more carrier fluids to maintain a usable consistency. This can dilute the concentration of the colorant, sometimes to as low as 10-15% of the overall composition, which can impact the pigment's effectiveness and longevity once implanted.

Thus, for producers, balancing these various factors can be akin to solving multiple Sudoku puzzles simultaneously. Each decision impacts another, requiring a finely tuned approach to achieve the optimal balance between particle size, stability, ease of implantation, consistency, and cost.